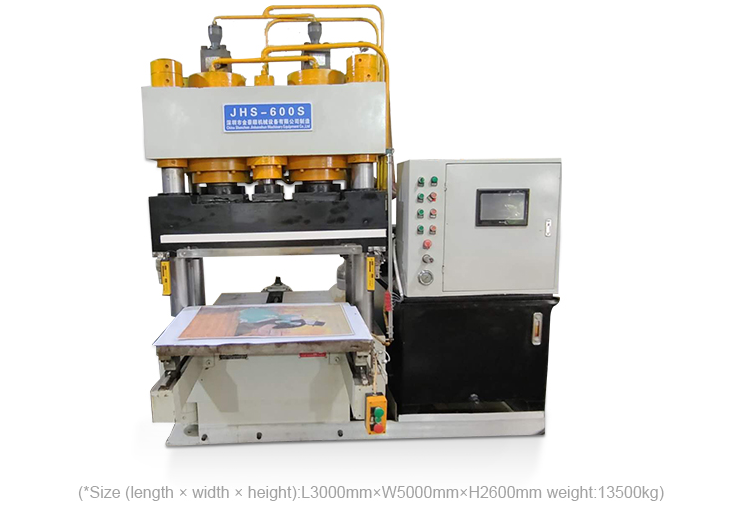

Product features

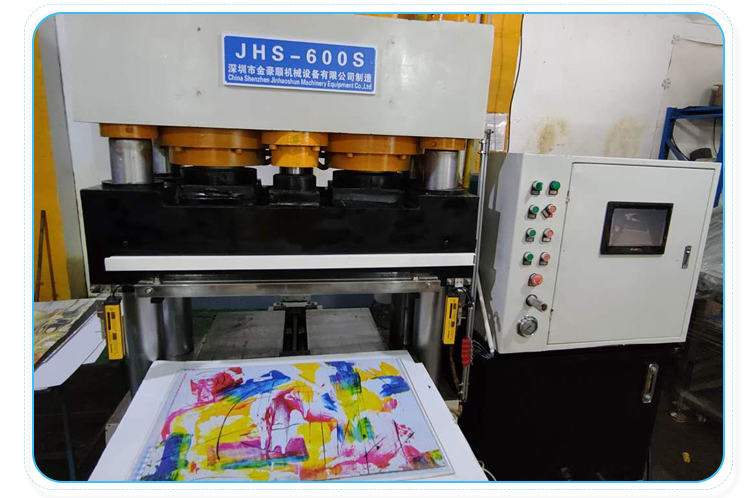

The CNC Hydraulic Servo Jigsaw Puzzle Cutter for 1000 piece puzzles combines advanced computer numerical control with powerful hydraulic servo actuation to deliver precise, high-speed cutting of complex puzzle shapes from materials such as cardboard, polywood, and plastic. Its robust hydraulic press, exerting forces between 600 to 1200 tons, ensures clean and accurate edges, while automated CNC controls and quick mold change features enhance production efficiency and flexibility. Designed for mass production, this cutter processes puzzles with 1000 to 3000 pieces per cycle at a rate of 7 to 10 puzzles per minute, making it ideal for large-scale puzzle manufacturing.

We serve

We serve precision, efficiency, and reliability with our CNC Hydraulic Servo Jigsaw Puzzle Cutter, designed specifically for 1000-3000 piece puzzles. Our advanced cutting technology ensures clean, accurate cuts every time, preserving the integrity of each puzzle piece. By integrating hydraulic servo control, we deliver smooth, consistent performance that boosts productivity and reduces material waste. We prioritize user-friendly operation, durability, and customizable settings to meet diverse production needs. Committed to supporting your manufacturing goals, we provide expert guidance and ongoing service to maximize your investment. With us, experience seamless puzzle cutting that elevates quality and efficiency.

Enterprise core strength

We serve precision, efficiency, and reliability with our CNC Hydraulic Servo Jigsaw Puzzle Cutter, designed specifically for puzzles ranging from 1000 to 3000 pieces. Our cutting-edge technology ensures ultra-smooth, accurate cuts that preserve the integrity of each puzzle piece, enhancing the overall assembly experience. We prioritize user-friendly operation and durability, delivering consistent performance to meet professional and enthusiast demands. With customizable settings and robust construction, our machine supports your creative production while minimizing waste. Committed to quality service, we provide expert support and timely solutions to help you bring intricate puzzle designs to life with confidence and ease.

JHS Machinery Equipment

JHS Machinery Equipment Mr. King

Mr. King

101, No. 41, Tongxin Middle Road, Central Community, Pingdi Street, Shenzhen, Guangdong, China

101, No. 41, Tongxin Middle Road, Central Community, Pingdi Street, Shenzhen, Guangdong, China