Utilizes computer numerical control (CNC) technology for precise positioning and cutting of puzzle pieces

Servo motors provide accurate and controlled movements for intricate puzzle shapes

● High-Speed Operation

Capable of cutting puzzles with 1000-3000 pieces in a single cycle at high speeds

Efficient production rates of around 7-10 puzzles per minute

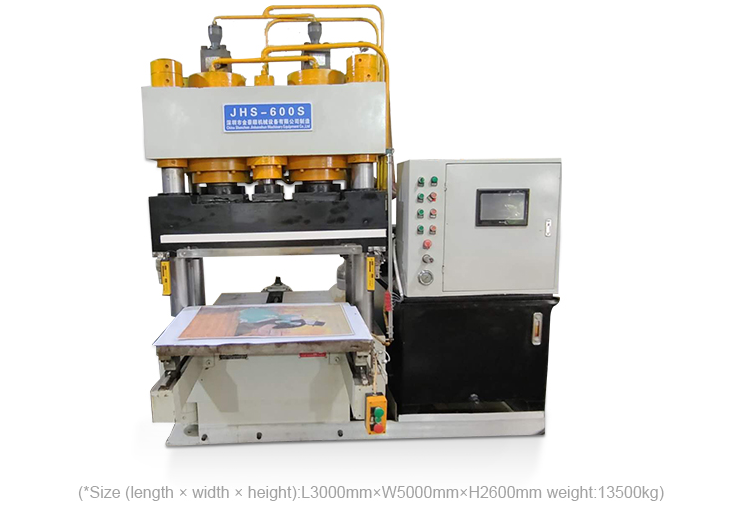

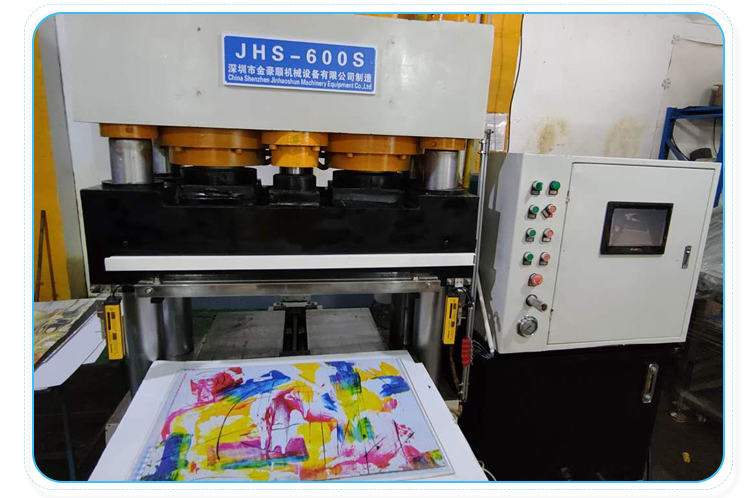

● Hydraulic Cutting Force

Equipped with powerful hydraulic presses exerting forces ranging from 600 to 1200 tons

Ensures clean and precise cuts through materials like cardboard, polywood, or plastic

● Automated and Efficient

Fully automated operation with PLC control and touchscreens

Quick mold/die change capability for different puzzle designs

JHS Machinery Equipment

JHS Machinery Equipment Mr. King

Mr. King

101, No. 41, Tongxin Middle Road, Central Community, Pingdi Street, Shenzhen, Guangdong, China

101, No. 41, Tongxin Middle Road, Central Community, Pingdi Street, Shenzhen, Guangdong, China